Understanding the Supply Chain of Palladium

Palladium, a precious metal with a wealth of applications, is capturing your attention as industries increasingly turn to sustainable solutions.

This overview of the palladium industry delves into extraction and production methods, explores its diverse uses, and sheds light on the global market dynamics influencing demand.

You ll also discover key players in the sector and examine the environmental impacts of palladium mining, emphasizing the significance of responsible practices.

Dive into the exciting world of palladium now and see its impact on our economy!

Contents

Key Takeaways:

- Palladium is a precious metal used in various industries, including automotive, electronics, and jewelry.

- The majority of palladium is mined in Russia and South Africa, raising environmental concerns about the extraction processes.

- Sustainability and responsible mining practices are essential for ensuring long-term availability and reducing environmental impact.

Overview of the Industry

The palladium industry presents you with an intricate web of supply chains and management practices that significantly impact various sectors, including healthcare, automotive, and electronics. As market conditions evolve and competitive advantages shift, you ll notice companies like Palladium and key stakeholders in countries like South Africa and the United States adapting their strategies to ensure operational efficiency and customer satisfaction.

Technology solutions enhance logistics and improve supply chain visibility.

In this dynamic landscape, logistics help is crucial, directly influencing the timely delivery of palladium and other essential materials.

Forming partnerships and using new solutions can give your business a strong edge in a globalized economy.

Influential figures, such as Dan Rhodes, play a pivotal role in navigating market trends and shaping industry practices, underscoring the necessity of an agile approach to supply chain management.

By continually assessing risks and opportunities, you position yourself to better respond to disruptions and enhance overall performance, ultimately delivering benefits to end-users across diverse markets.

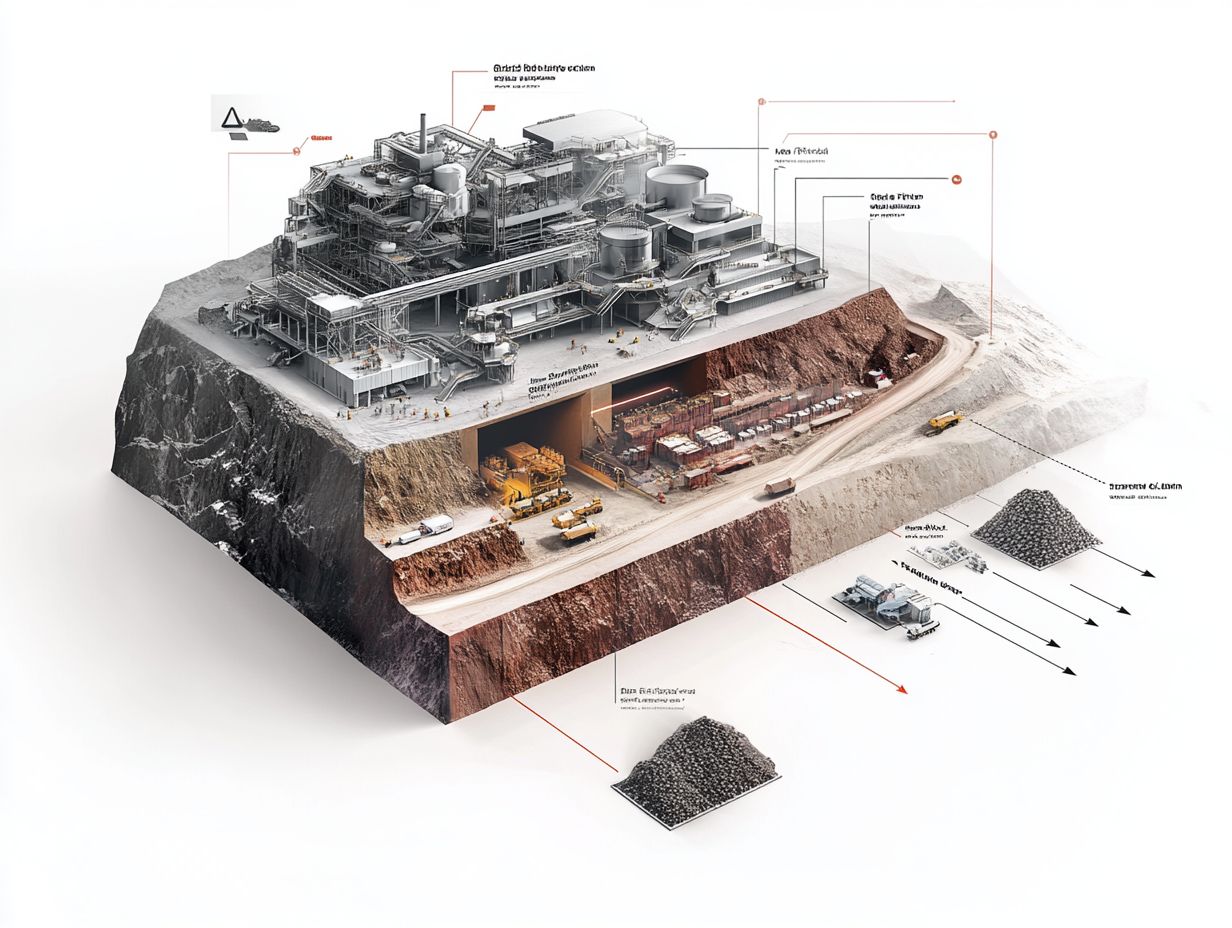

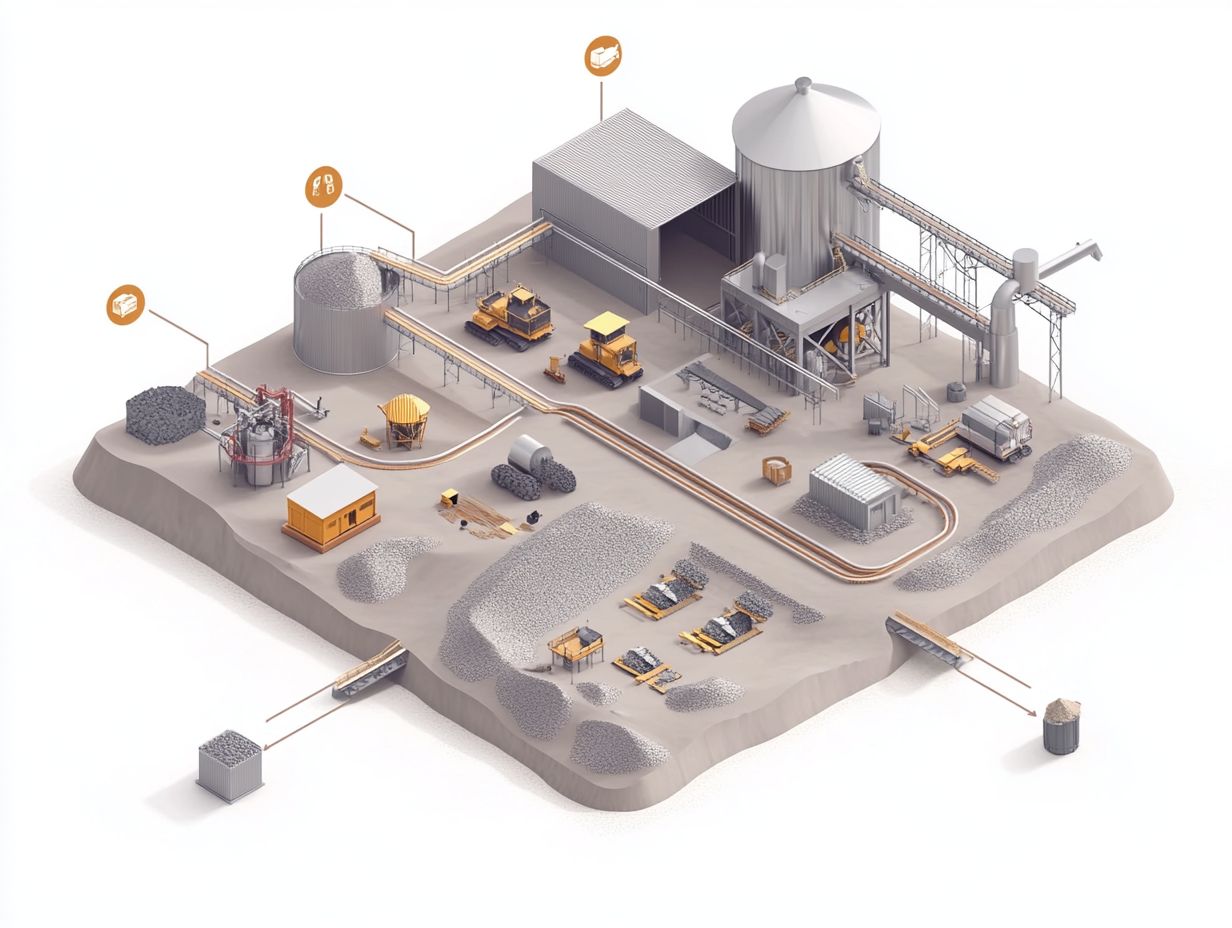

Extraction and Production of Palladium

Palladium extraction and production encompass intricate supply chains that traverse multiple regions, particularly South Africa and Russia. Here, mining practices are expertly designed to optimize yield while minimizing environmental impact.

The extraction process is shaped by a variety of production procedures that require meticulous management to ensure sustainability and adherence to industry standards.

Methods and Techniques Used

The methods and techniques employed in palladium extraction utilize cutting-edge technologies such as data science, automation, and machine learning. These innovations enhance your operational efficiency and optimize the overall effectiveness of your supply chain.

Using data to predict future trends can help you fine-tune resource allocation and anticipate potential disruptions, cultivating a more resilient extraction process.

Automation significantly curtails human error while boosting throughput, and data science delivers insights that guide your decision-making at every phase.

With the integration of real-time monitoring systems, you can swiftly address issues before they escalate, minimizing downtime and saving costs.

These advancements not only streamline your operations but also contribute to sustainability by reducing waste and energy consumption, aligning perfectly with industry objectives for environmentally responsible extraction practices.

Uses and Demand for Palladium

The demand for palladium is significantly influenced by its wide-ranging applications across multiple industries, such as automotive, electronics, and healthcare. In these sectors, demand forecasting means predicting how much of a product will be needed, which is essential for efficient inventory management and maintaining quality assurance.

As these industries continue to evolve, the need for strong supply chain management becomes paramount to effectively meet customer demand.

Industries and Products that Rely on Palladium

Industries that lean heavily on palladium include the automotive sector, where it plays an essential role in catalytic converters. It also impacts the electronics and healthcare sectors, where its unique properties offer a competitive edge.

In the automotive world, palladium is key to reducing harmful emissions, which directly influences vehicle design and helps meet stringent environmental regulations.

The electronics industry harnesses palladium for manufacturing connectors and capacitors, crucial elements that enhance device performance and longevity.

In healthcare, palladium-based compounds are becoming increasingly vital in diagnostic tools and treatments, highlighting their versatility and significance.

This heavy reliance on palladium helps improve production processes. Fluctuations in palladium availability can dramatically affect manufacturing timelines and costs across these sectors.

Discover the Thriving Global Market for Palladium

The global palladium market has been intricately influenced by shifting market trends and substantial financial investments from key players, crafting a competitive edge for those who effectively engage stakeholders within the industry.

Grasping these dynamics is essential for anticipating future movements and aligning your business strategies effectively.

Key Players and Trends

Key players in the palladium market are significantly influenced by prevailing economic factors and market conditions, which shape their strategies and partnerships. By understanding the actions of these key players and the trends they pursue, you can gain valuable insights into the industry’s future.

These entities include major mining companies and industrial stakeholders who not only extract palladium but also lead the way in refining and processing innovations.

Major market players like Norilsk Nickel and Anglo American Platinum play pivotal roles in shaping supply strategies, dynamically responding to the automotive sector’s fluctuating demand and investment trends.

Their strategic alliances, such as joint ventures with technology firms, pave the way for enhanced production methods and sustainable practices. By adapting to regulatory changes and exploring new market opportunities like the rapidly growing electric vehicle industry, they showcase resilience and foresight, reinforcing their competitive advantage in the ever-evolving palladium market landscape. For those interested in related trends, understanding the silver supply chain can provide valuable insights.

Environmental Impact of the Palladium Supply Chain

The environmental impact of the palladium supply chain is a pressing concern, prompting a shift towards sustainable practices and the creation of green supply chains designed to minimize ecological footprints.

Companies are increasingly prioritizing resource optimization, ensuring their operations are not only profitable but also environmentally responsible.

Stay informed about palladium’s journey and its impact on our world!

Sustainability and Responsible Mining Practices

Sustainability and responsible mining practices are crucial in the palladium industry. These practices minimize environmental impact and maximize stakeholder engagement.

To achieve this, companies like yours are increasingly adopting thorough environmental management plans and investing in cutting-edge technologies that reduce carbon emissions and minimize habitat disruption. By actively involving local communities and other stakeholders, you can foster a collaborative approach that prioritizes transparency and accountability.

Education programs designed to inform stakeholders about sustainable practices are gaining traction, empowering you to participate meaningfully in decision-making processes. Embracing circular economy principles which focus on reusing and recycling materials ensures that resources are utilized efficiently, preserving natural ecosystems for future generations.

Your dedication to sustainable practices can pave the way for success in the mining sector.

Frequently Asked Questions

Curious about the palladium supply chain?

The supply chain of palladium refers to the process of extracting, refining, and distributing this precious metal to its various end users. This includes mining companies, refiners, manufacturers, and ultimately, consumers.

Where is palladium mined?

Palladium is primarily mined in two countries: Russia and South Africa. These two countries account for the majority of global palladium production, with smaller amounts also mined in Canada, the United States, and Zimbabwe.

What is the role of refiners in the palladium supply chain?

Refiners play a crucial role in the palladium supply chain by processing raw palladium material into a usable form. This includes smelting, purification, and preparation for distribution to manufacturers.

Who are the main consumers of palladium?

The main consumers of palladium are the automotive, electronics, and jewelry industries. These industries use palladium for its unique properties, such as its high resistance to corrosion and ability to conduct electricity.

How does the supply chain of palladium impact its price?

The supply chain of palladium can have a significant impact on its price. Factors such as mining production, refining capacity, and demand from end users can all affect the availability and cost of palladium in the market.

Is the supply chain of palladium environmentally sustainable?

The supply chain of palladium, like any mining industry, can have negative impacts on the environment. However, steps are being taken to improve sustainability, such as implementing responsible mining practices and increasing recycling efforts.