Understanding Platinum’s Role in Catalytic Converters

Ever wondered how your car cleans up its act? Catalytic converters are the key! They are essential for minimizing harmful emissions from vehicles, and at the core of this technology is platinum.

This precious metal helps change harmful gases into safer ones, prompting vital questions about where it comes from and its environmental impact.

In this article, you will explore the functions of platinum in catalytic converters. You will also look into the mining and production processes involved, examine the ecological concerns tied to its extraction, and consider future possibilities for alternatives.

Embark on this journey as you uncover the intricacies of platinum s role in advancing cleaner automotive technologies.

Contents

- Key Takeaways:

- The Role of Platinum in Catalytic Converters

- Platinum Mining and Production

- Environmental Impact of Platinum Mining

- Future of Platinum in Catalytic Converters

- Frequently Asked Questions

- What is the role of platinum in catalytic converters?

- Why is platinum used in catalytic converters instead of other metals?

- What is a catalytic converter?

- How much platinum is typically used in a catalytic converter?

- Does the platinum in catalytic converters ever need to be replaced?

- What happens to the platinum in a catalytic converter at the end of its life?

- Are there any potential health or environmental concerns associated with platinum in catalytic converters?

Key Takeaways:

- Platinum reduces harmful emissions from vehicles.

- Mining platinum can harm the environment.

- Alternatives to platinum are being explored to lessen this impact.

What are Catalytic Converters?

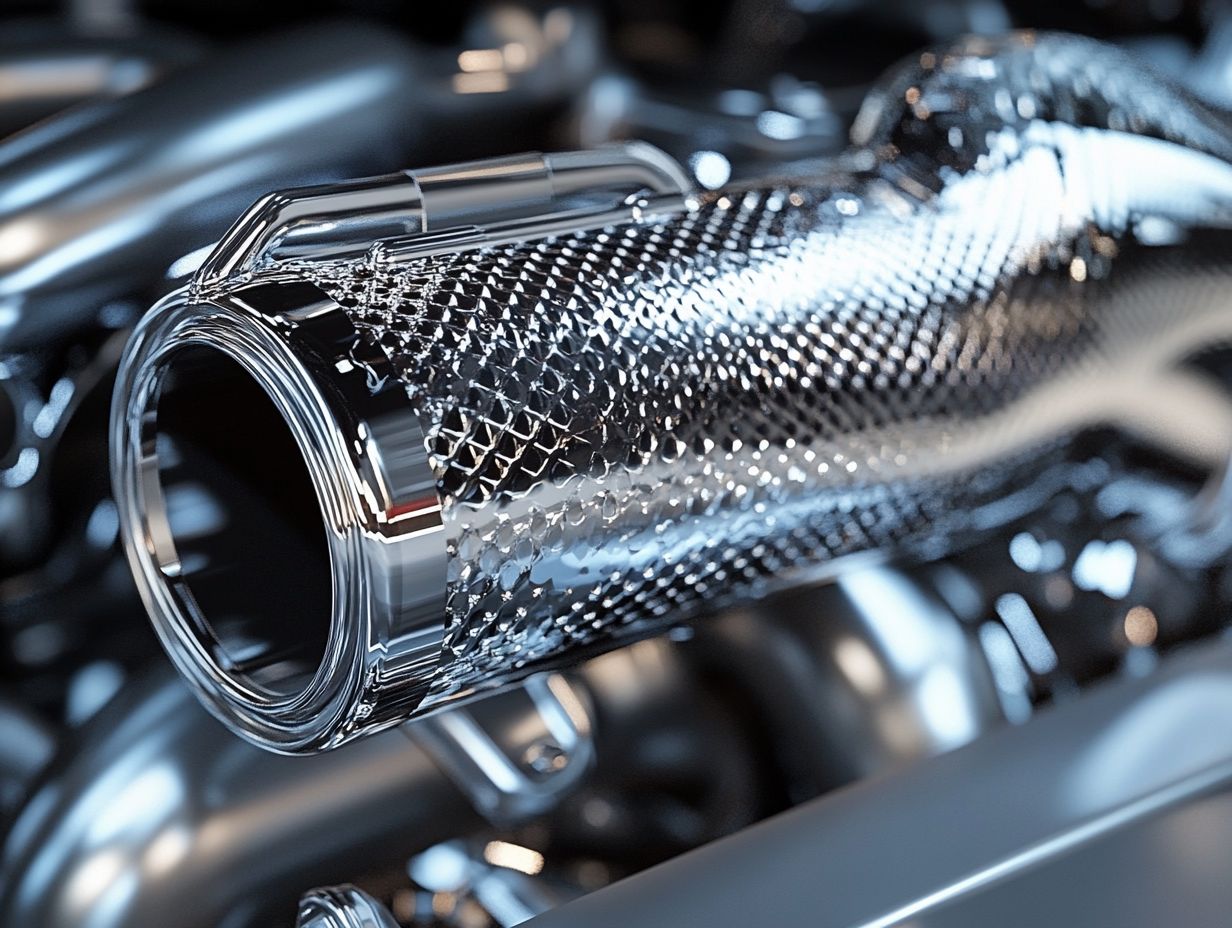

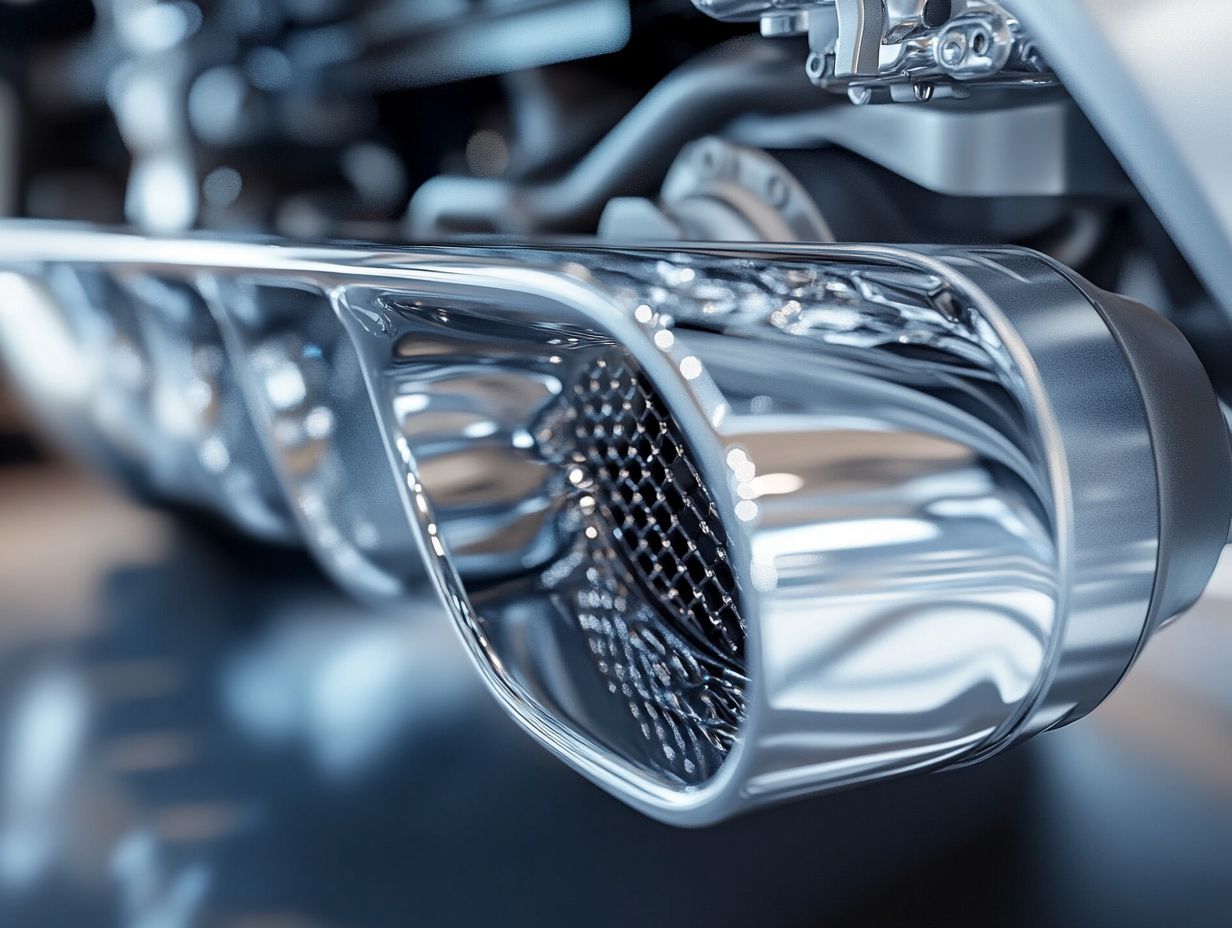

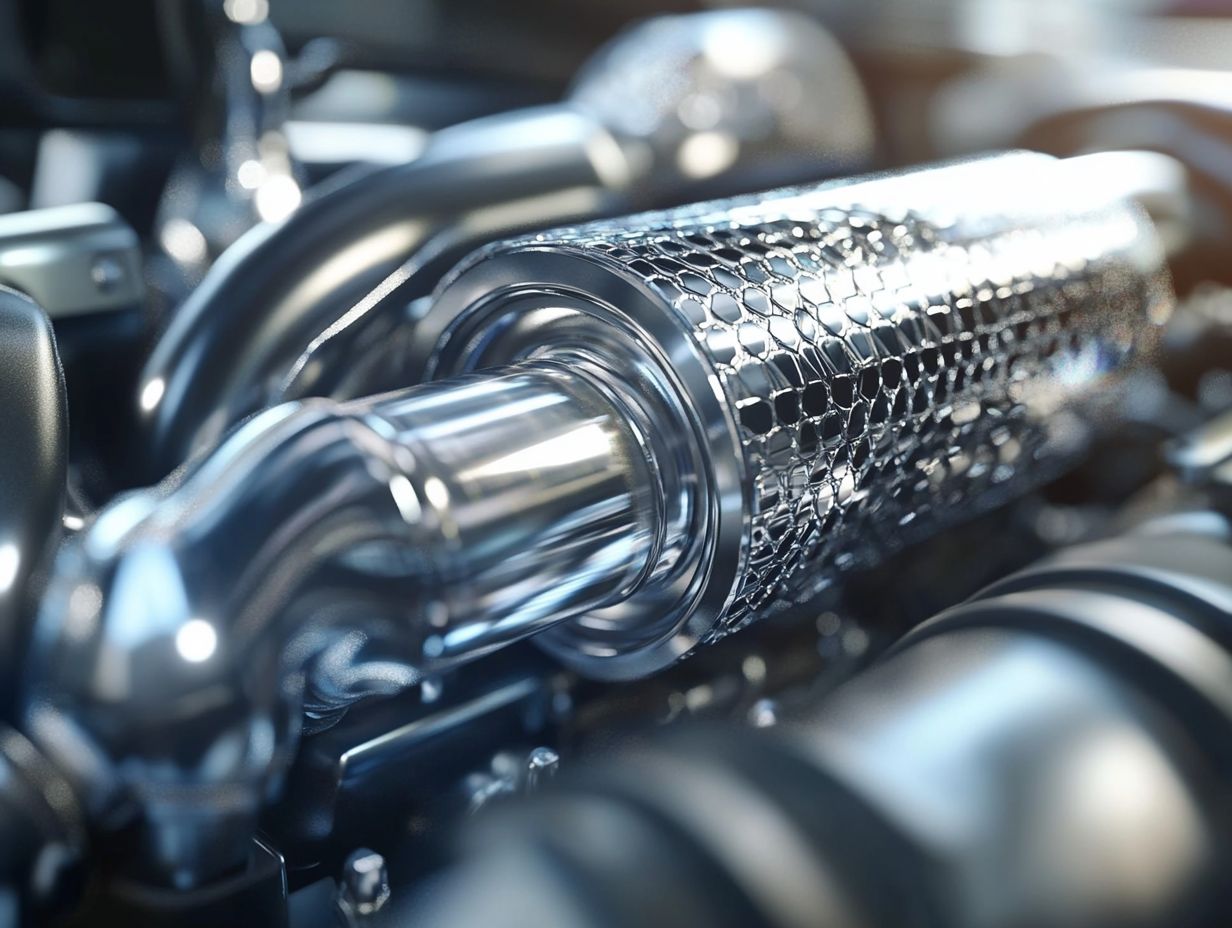

Catalytic converters are critical components in modern exhaust systems. They are carefully designed to reduce harmful automotive emissions, such as nitrogen oxides, hydrocarbons, and carbon monoxide.

This not only enhances air quality but also ensures compliance with strict rules about pollution.

Through the use of special metals that help speed up chemical reactions, these devices help change harmful gases into safer ones. They transform toxic gases generated during combustion into far less harmful substances.

In this way, they play a crucial role in boosting the efficiency of internal combustion engines. They also contribute to the health of your community and the sustainability of the environment.

By preventing these noxious emissions from entering the atmosphere, catalytic converters help mitigate the impact of air pollution. This is vital for protecting both ecosystems and human health.

As governments worldwide enforce stricter regulations aimed at curbing vehicular emissions, the importance of this technology becomes increasingly clear. It underscores its essential role in fostering cleaner transportation solutions.

The Role of Platinum in Catalytic Converters

Platinum plays a crucial role in catalytic converters. It serves as one of the most effective precious metals in enhancing the conversion of harmful emissions into less toxic substances.

This not only elevates the value of catalytic converters but also greatly improves how well they work in automotive technology.

Why is Platinum Used?

Platinum is the go-to choice for catalytic converters, and it’s easy to see why. Its exceptional ability to facilitate oxidation and reduction reactions is key for changing harmful automotive emissions into far less toxic byproducts.

This precious metal shines in promoting chemical transformations at lower temperatures, which means it efficiently breaks down pollutants like carbon monoxide and hydrocarbons.

Its impressive stability and resistance to poisoning guarantee long-lasting performance, making it a favored option among manufacturers.

By significantly curtailing toxic emissions, platinum plays a crucial role in helping you meet strict rules about pollution. This not only leads to cleaner air and better public health outcomes but also contributes to a reduced ecological footprint for vehicles on the road.

Therefore, it s not merely about performance; it s the commitment to sustainability that makes platinum a critical component of modern automotive technology.

How Platinum Helps Reduce Emissions

Platinum significantly reduces vehicle emissions by catalyzing reactions that transform nitrogen oxides, hydrocarbon emissions, and carbon monoxide into harmless nitrogen gas and carbon dioxide. This makes it an essential component of the three-way catalyst system found in modern catalytic converters.

This catalytic process unfolds through three pivotal reactions:

- The oxidation of carbon monoxide into carbon dioxide.

- The reduction of nitrogen oxides into nitrogen gas.

- The oxidation of unburned hydrocarbons into carbon dioxide and water.

By facilitating these critical transformations, platinum plays a vital role in diminishing the levels of harmful pollutants released into the atmosphere. As stricter global emissions regulations emerge, the efficiency of catalytic converters that depend on platinum becomes crucial. This ensures that vehicles meet these standards and contribute to cleaner air and a more sustainable environment.

Platinum Mining and Production

Platinum mining and production are vital for securing the precious metal required for manufacturing catalytic converters. Companies like Johnson Matthey play a significant role in the extraction and refining of platinum, navigating fluctuating mining costs that influence the automotive industry.

Understanding these dynamics helps you appreciate the balance between resource extraction and market demands.

Sources of Platinum

The primary sources of platinum include platinum-group metals (PGMs) extracted from various regions. South Africa is the largest producer and an essential player for automotive applications like catalytic converters.

Russia is also a significant contributor, enhancing the global supply of this precious metal. Other key mining countries, such as Zimbabwe and Canada, are crucial in the extraction process.

The importance of these geographical sources is paramount, especially as the automotive industry increasingly relies on platinum to reduce harmful emissions. As manufacturers strive to meet stringent environmental regulations, the demand for platinum remains strong, highlighting its vital role in promoting cleaner transportation solutions worldwide.

Extraction and Refining Processes

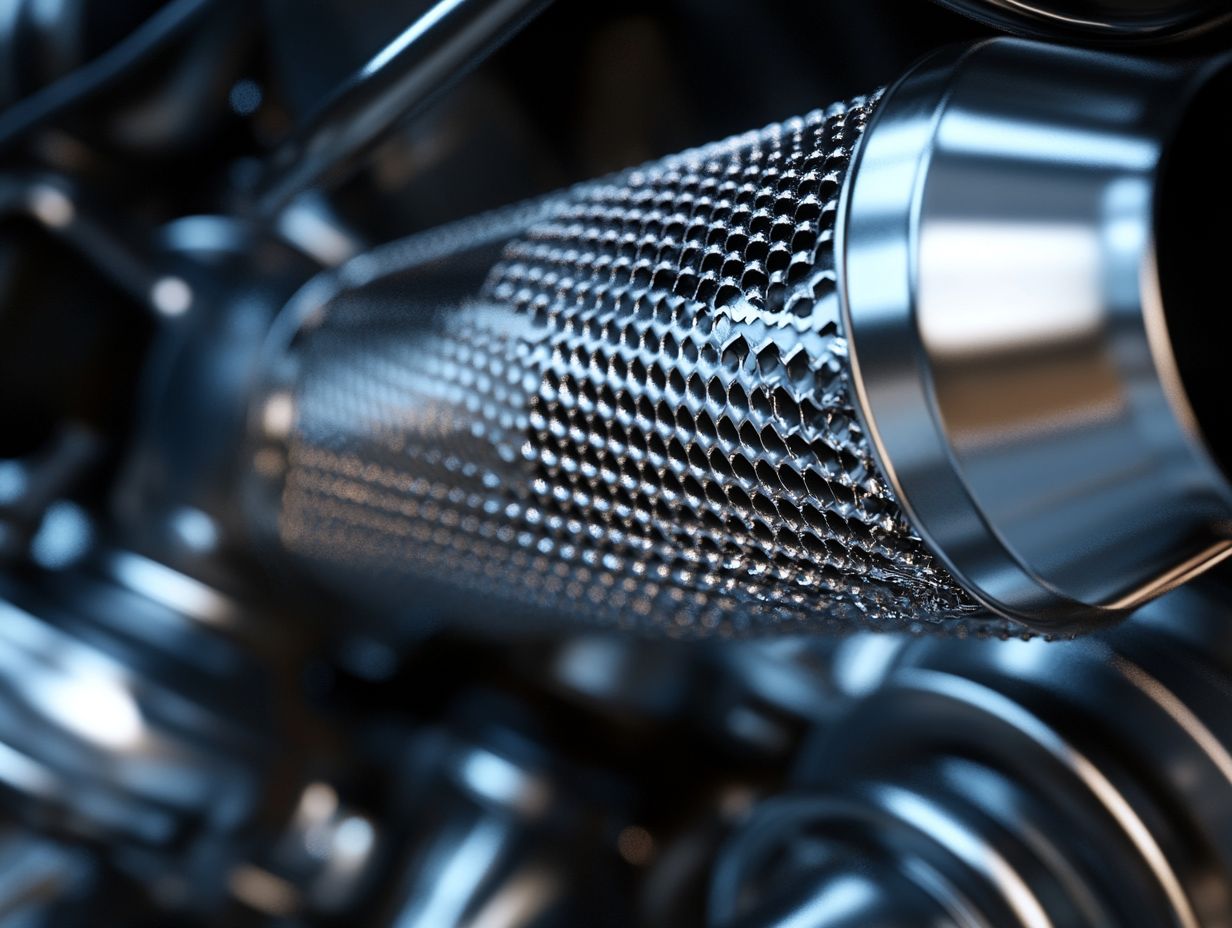

The extraction and refining processes of platinum are designed to ensure efficient recovery of precious metals from ore. Organizations like Johnson Matthey employ advanced methodologies to minimize mining costs while enhancing yields.

Your journey begins with the meticulous mining of platinum-bearing ore. Technologies such as minimally invasive hydraulic drilling and cutting-edge underground mining automation are pivotal. Once the ore is extracted, it undergoes crushing and milling, liberating valuable platinum particles. Following this, separation processes like flotation and magnetic separation isolate platinum from other metals.

Then, hydrometallurgical and pyrometallurgical techniques refine the platinum to a purity level that meets the demands of applications such as catalytic converters. These innovative methods enhance the effectiveness of platinum recovery and transform the industry, contributing to the production of cleaner vehicle emissions.

Environmental Impact of Platinum Mining

The environmental impact of platinum mining raises significant concerns, particularly regarding its effects on land and water. This process often leads to issues like acid precipitation and contributes to vehicle pollution.

It’s essential to navigate the delicate balance between extraction and sustainability, ensuring that resource utilization does not come at the expense of the environment.

Effects on Land and Water

Platinum mining often results in significant land degradation and water pollution. Activities frequently cause acid rain and disturb local ecosystems. This highlights the urgent need for responsible mining practices.

When extracting platinum, the removal of vegetation and topsoil disrupts habitats. This leads to soil erosion and makes areas more susceptible to floods and landslides. The chemicals used in refining processes can seep into nearby water bodies, endangering aquatic life and contaminating drinking water sources for local communities.

In the long run, these environmental impacts can compromise agricultural productivity and disrupt the livelihoods of those who rely on the land and water for their survival. Therefore, addressing these consequences is vital for ensuring sustainable development and maintaining the delicate balance of local ecosystems.

Efforts to Reduce Environmental Impact

Efforts to reduce the environmental impact of platinum mining are now leading the way! The focus is squarely on sustainable mining practices and adherence to rigorous environmental standards that promote corporate responsibility and eco-friendly operations.

Given growing environmental concerns and societal expectations, mining companies like yours are adopting innovative strategies to minimize ecological footprints. By integrating advanced technologies such as water recycling systems and renewable energy sources you not only comply with regulatory frameworks but also contribute to restoring ecosystems affected by extraction activities.

Engaging local communities in decision-making processes fosters a spirit of collaboration and enhances accountability for environmental stewardship. This collective commitment to sustainability aligns with governmental regulations and resonates with an increasingly environmentally-conscious consumer base, paving the way for a greener future in the mining sector.

Future of Platinum in Catalytic Converters

The future of platinum in catalytic converters is being intricately shaped by technological advancements and the rise of potential alternatives. As you navigate the automotive industry’s shift towards eco-friendly vehicles, it s essential to consider how exploring the hydrogen economy could significantly influence the demand for precious metals.

Potential Alternatives and Advancements

As you navigate the evolving landscape of automotive technology, researchers are exploring potential alternatives to platinum in catalytic converters. These advancements are paving the way for other metal catalysts that offer similar efficiencies and align seamlessly with the shift toward eco-friendly vehicles.

Alternatives like palladium, alongside various non-precious metals such as copper and nickel, are being studied for their effectiveness in reducing harmful emissions. Research suggests that some of these materials can match platinum’s performance while delivering significant cost savings and mitigating the environmental toll linked to mining precious metals.

The exploration of innovative composite materials is gaining momentum, potentially ushering in a more sustainable approach within the automotive industry. As the demand for greener solutions intensifies, these alternatives could play a pivotal role in shaping the future of catalytic converter technology.

Frequently Asked Questions

What is the role of platinum in catalytic converters?

Platinum is a key component in catalytic converters, where it acts as a catalyst to speed up the chemical reactions that convert harmful pollutants into less harmful substances.

Why is platinum used in catalytic converters instead of other metals?

Platinum is preferred for its high catalytic activity and ability to withstand high temperatures and corrosive environments, making it ideal for use in catalytic converters. Alternatives like palladium are also being considered for their effectiveness.

What is a catalytic converter?

A catalytic converter is an essential component of a vehicle’s exhaust system. It helps reduce harmful emissions by converting them into less harmful substances.

How much platinum is typically used in a catalytic converter?

A catalytic converter usually contains 3 to 7 grams of platinum. This amount varies based on the vehicle’s size and type.

Does the platinum in catalytic converters ever need to be replaced?

In most cases, the platinum lasts a long time. If the converter is damaged or clogged, you may need to replace it, which includes changing the platinum.

What happens to the platinum in a catalytic converter at the end of its life?

At the end of its life, a catalytic converter can be recycled. This process recovers platinum and other valuable metals, reducing the need for new platinum and minimizing waste.

Are there any potential health or environmental concerns associated with platinum in catalytic converters?

Platinum in catalytic converters is regulated to protect human health and the environment. Proper disposal of used converters prevents harmful substances from entering our surroundings.